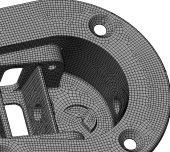

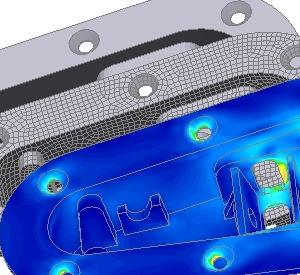

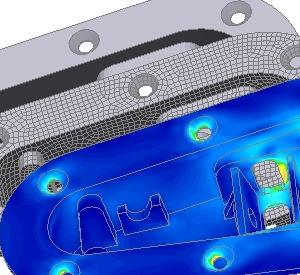

Mechanical and Structural Simulation

Using simulation to predict mechanical perfomance is a great way to reduce time and costs in the

product development process. We can take your ideas and simulate how they are going to perform in the real world.

Applying FEA to carry out virtual testing for strength, deflection, stress concentration and fatigue we can quickly

identify areas of concern. So we can explore and optimise all of your ideas whilst saving money and time.

Click above for more.

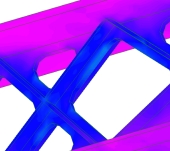

Thermal Simulation

![]()

We simulate heat transfer to develop thermally optimised designs. Understand the thermal response so

that you can drive the development of reliable products, quickly and for less. We can examine everything from electronics

cooling to high temperature creep. Couple this with mechanical analysis to look at thermal stress or degradation.

Couple it with fluids for convection. If you have got thermal needs we can help. Click above for more.

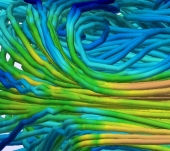

Fluid Flow CFD

Analysis of fluid flows of gas and liquids using computational fluid dynamics provides insight into

how the shape of your design will influence the flow rate, velocity and turbulence produced in operation. This insight will

allow design optimisation of all fluid contact areas, this can be applied to fan and pump designs, HVAC, aerodynamic,

hydrodynamics, porous materials, and many more. If your innovation is experiencing turbulence we can help! Click above for more.

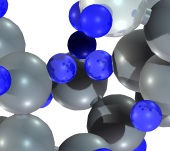

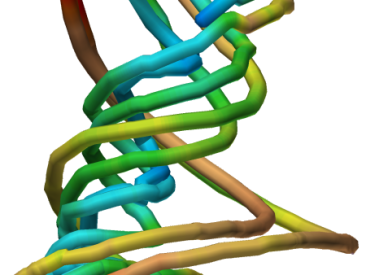

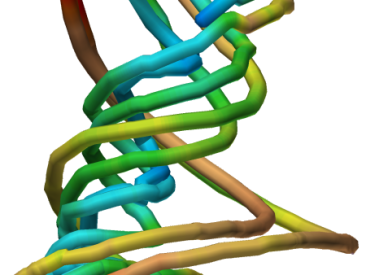

Materials Selection and testing

Your choice of material will greatly influence the sucess of your product. To have a full characterisation of the

material will help you to decide how to use it in your design and how to take advantage of its properties. We will identify, test and

source candidate materials for you to ensure you leverage your product success. Click above for more.